New process could help recycle wind turbine blades

Listen

(Runtime 0:54)

Read

Lots of wind turbines built in the 1990s are getting old, which means their parts can end up in landfills. Researchers have discovered a process that could be used to recycle the giant blades – and repurpose the leftovers to create plastic.

The process is simple, said Jinwen Zhang, a Washington State University professor and co-author of the paper, published in the journal Resources, Conservation and Recycling.

First, they chop the massive blades into 2-inch blocks. Then, they soak small pieces using pressurized, superheated water in a bath of low-toxicity salt for about two hours. That solvent breaks down the glass fiber-reinforced polymer, or GFRP, that’s used to build the turbines.

“It works very well, especially considering the mild conditions that we applied,” said Cheng Hao, a former graduate student in the School of Mechanical and Materials Engineering and co-first author on the paper, in a news release.

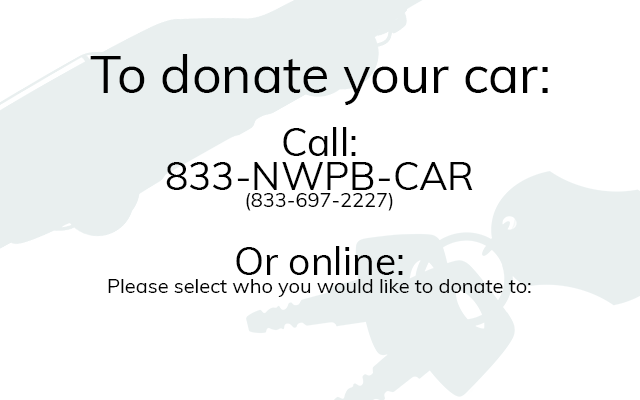

Pictured from left to right, wind turbine blade waste; treated and dried wind turbine blade glass fiber-reinforced polymer (GFRP); and injection-molded plastic containing 70% recycled GFRP (Courtesy: Washington State University)

The mild solution is known as zinc acetate. It’s often used in things like throat lozenges and food additives, according to the release. During the process, the researchers were also able to recycle and reuse most of the zinc acetate.

Glass fiber-reinforced polymers are notoriously hard to recycle. They don’t melt like other plastics do, Zhang said.

However, once they’re broken down from this new process, the resulting glass fibers and resins can be mixed with plastics that are moldable at high temperatures and used again, likely in manufacturing, he said.

“Carbon glass fibers are widely used in different industry products,” Zhang said in an interview. “For example, that can be used for some automobile parts.”

That will be important as more wind turbines reach the end of their lifespan, he said. The glass fibers make up about two-thirds of the wind turbine’s weight, according to the paper. It estimated wind turbine blades could “reach 100,000 tons per year in Europe alone.”

In the U.S., according to the Department of Energy, 2,307 blades from 12 wind energy projects were taken out of service in 2021.

By 2050, the department’s WINDExchange platform estimates, turbine blade waste would be roughly 0.15% of the municipal solid waste and construction and demolition waste that was thrown away in 2018.

“As wind energy grows, recycling and reusing wind turbine waste is becoming increasingly urgent,” Zhang said, in the news release.

Zhang said the researchers plan to continue looking at ways to make the process more efficient. While it’s a relatively cost-effective solution because it doesn’t use complex chemicals, that would make it easier to scale up, he said. One day, they also hope to develop completely recyclable wind turbine blades.